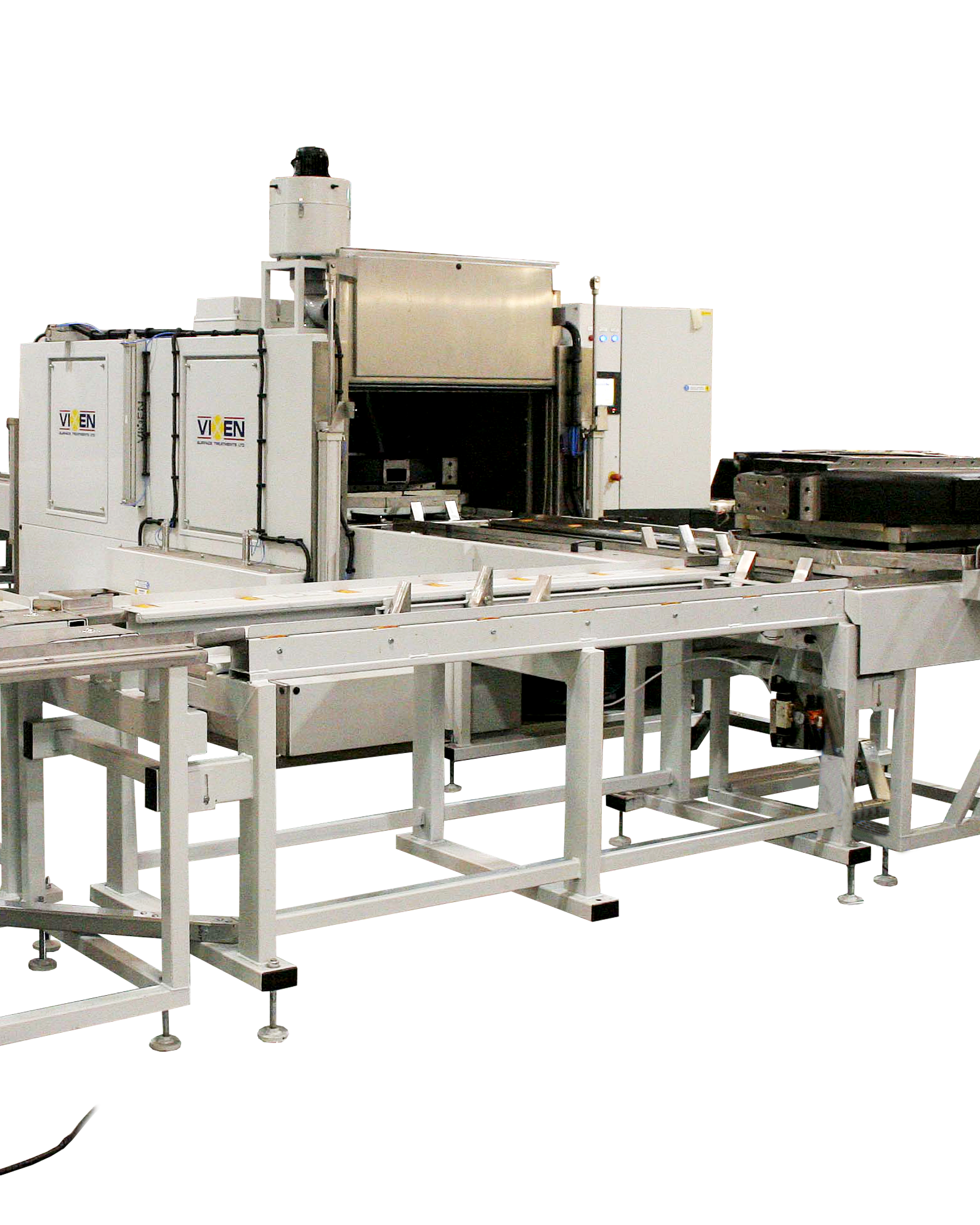

Sledge Wash

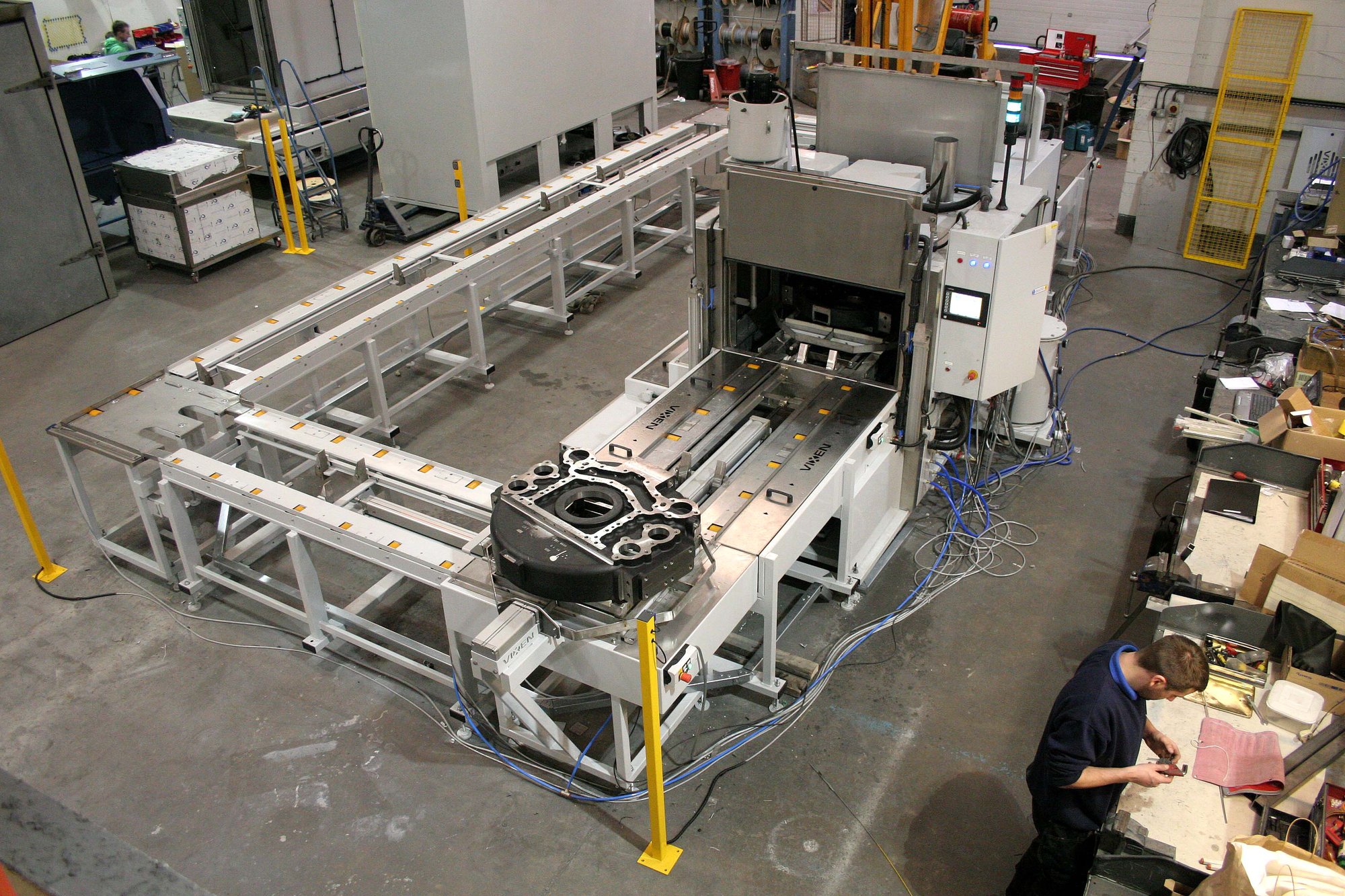

Our sledge solutions can be built in any configuration to fit into or around your current manufacturing needs and can be integrated to work with or a long side current processes.

Baskets are loaded with components onto the Sledge Wash machine and then pushed along the tracks in a sledge-like movement to be processed.

Sledge Wash Solutions

Custom-Built, Multi-Stage Washing Systems with Minimal Manual Handling

Vixen’s Sledge Washers are tailor-made to meet the exact needs of each customer, offering maximum flexibility in design, size, and functionality.

These machines can be configured with multiple wash stages—from pre-wash and main wash to rinse and drying—providing a complete and efficient cleaning solution for a wide range of components. Each system is built to any size required, ensuring seamless integration into your existing workflow and facility layout.

A key advantage of the Sledge Washer design is its focus on reducing manual handling. Components are loaded into baskets and moved along tracks in a controlled, sledge-like motion through each stage of the process, streamlining operations and improving safety.

Each unit is PLC controlled and can be operated using leading systems such as Siemens or Mitsubishi, offering precise and consistent wash cycles for repeatable, high-quality results.

Key Features:

-

Multiple wash stages available (customizable)

-

Built to any size to match your requirements

-

Automated movement to reduce manual handling

-

PLC control using Siemens or Mitsubishi systems

-

Consistent and repeatable cleaning for high-throughput environments

Whether you’re looking for a compact two-stage system or a fully automated multi-stage washer, Vixen’s Sledge Washers are built to perform.

Process driven solutions

Our aim is to work with you and supply you the process and solution(s) to meet your requirements. This can be done with one of our manual or automatic solutions.

Our equipment is designed with our process and your requirements in mind whilst utilising our years of experience and process knowledge we can provide a complete solution that delivers control and consistency to give you the perfect finish every time.

Go to our solution page or contact us below