Cutting Hob Pre & Post Coating prep

Add efficiency, consistency and repeatability to your processing with wet blasting

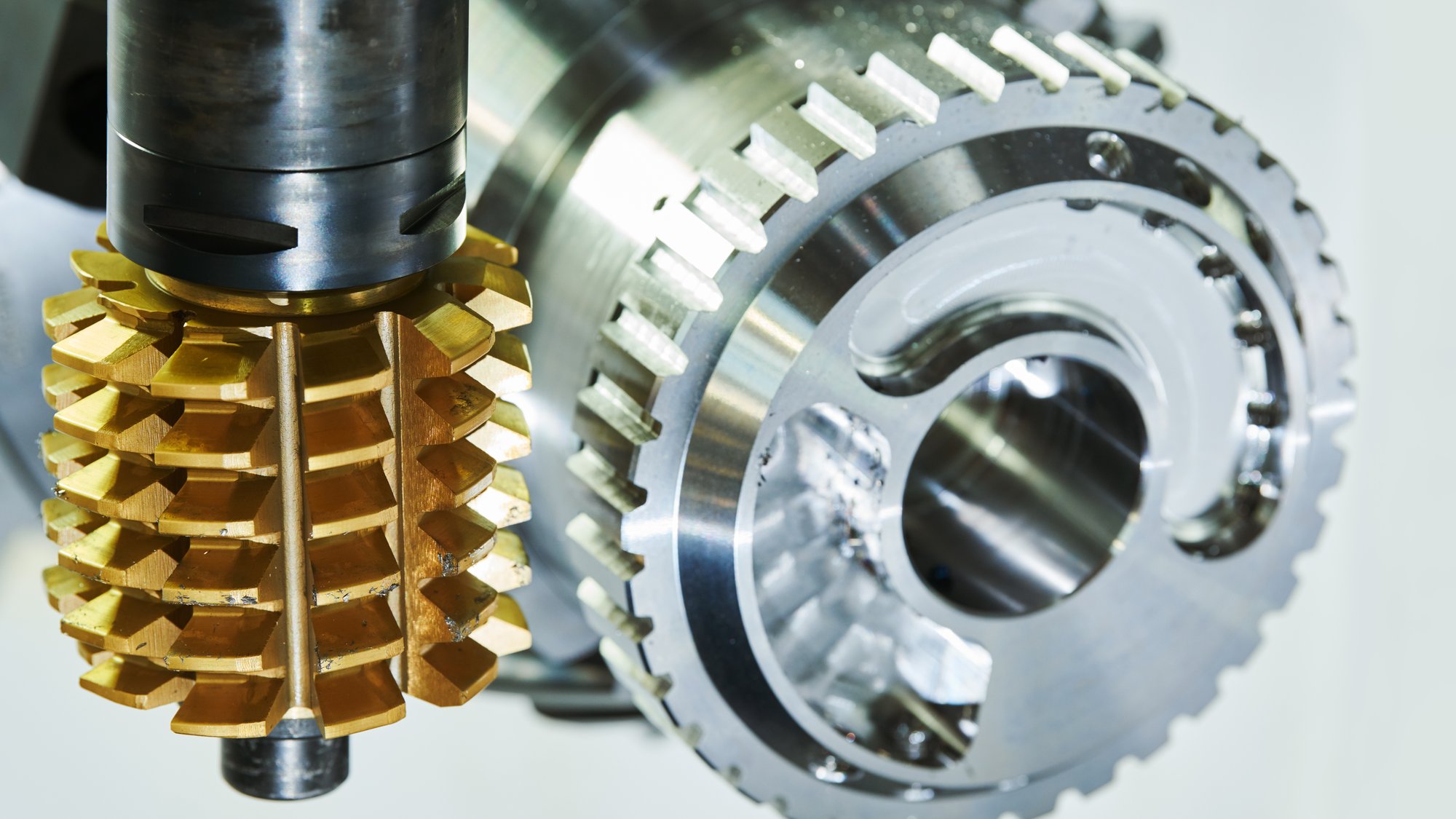

Wet blasting cutting hobs involves using a slurry of water, abrasive media, and sometimes additives to clean, finish, or texture the surfaces of cutting hobs.

Cutting hobs are precision tools used in gear cutting and shaping processes. Wet blasting can provide several benefits in the maintenance and preparation of cutting hobs to extend the life of the tool through various applications, such as consistent and repeatable edge prep and coating adherence.

Wet blasting Applications for Cutting Hobs

Resharpening and Regrinding: Removing wear, dullness, and imperfections from the cutting edges of hobs. Extends the lifespan of cutting hobs by restoring sharpness and cutting performance.

Deburring and Edge Radiusing: Removing burrs, sharp edges, or irregularities from the cutting edges and applying specific edge radii. Reduces damage on startup and enables for a even and high level of adhesion for coating.

Surface Smoothing: Smoothing out rough surfaces on cutting hobs. Reduces friction during cutting, minimizes heat generation, and improves overall cutting performance.

Cleaning and Degreasing: Removing coolant residues, oils, or contaminants from the surfaces of cutting hobs. Maintains a clean hob surface for improved chip evacuation, heat dissipation, and machining accuracy.

Selective Material Removal: Targeted removal of material from specific areas for precision shaping or adjustment. Allows for controlled material removal without compromising the overall integrity of the cutting hob.

Surface Finishing and Texture Control: Achieving a specific surface finish or texture on hob surfaces. Customizes the hob surface for enhanced chip flow, improved wear resistance, or other application-specific requirements.

Preparation for Coating: Creating an optimal surface for coatings to improve wear resistance. Enhances the adhesion of coatings, increasing the hob's lifespan and resistance to wear, abrasion, and corrosion.

Quality Control: Inspecting and removing defects, irregularities, or imperfections from the surface of cutting hobs. Improves the overall quality and performance of the cutting tools.

Environmental Considerations: Wet blasting reduces airborne dust and contaminants during surface preparation, contributing to a cleaner and safer working environment.

Wet blasting parameters, such as abrasive media type, water pressure, and dwell time, can be adjusted to suit the specific characteristics of cutting hobs and the desired outcome for their application in gear cutting and shaping processes.

Wet blast process benefits

Our wet blasting process offers several inherent benefits that add to it being the prefeed surface processing method for many industries and applications. Some of the key process benefits are listed below.

Highly controllable Surface Treatment: Wet blasting is a highly controllable process compared to other methods such as dry blasting. It can effectively remove contaminants, coatings, burrs and rust without causing damage to delicate automotive components, ensuring the integrity of the surfaces.

No Dust Emission: The addition of water in wet blasting suppresses dust formation, resulting in a cleaner and safer working environment. This is crucial in the automotive industry where cleanliness is essential for maintaining high-quality standards, and ensuring the health and safety of workers. This also means no static build up or hazardous environments that can occur with some materials.

Environmentally Friendly: The use of water in wet blasting minimizes the environmental impact compared to dry blasting methods. It reduces airborne dust and facilitates easier containment and disposal of waste, contributing to environmental sustainability.

Versatility in Abrasive Media: Wet blasting can utilize a variety of abrasive media, such as glass beads, aluminium oxide, Ceramics, or others, and, due to the high level of control the process, can also work wider a wider range of media sizes, from large coarse media, to very fine if the requirement calls for it. This versatility allows manufacturers to choose the most suitable media for specific applications, providing flexibility in surface preparation.

Improved Surface Finish: Wet blasting not only cleans surfaces but also leaves them with a smoother finish. This is particularly beneficial for applications where a high-quality appearance is crucial, such as in the production of automotive parts with aesthetic requirements.

Minimized Heat Generation: Wet blasting generates less heat compared to some methods. This is advantageous for components that are sensitive to heat, preventing potential damage or distortion during the process.

Reduced Media Consumption: Wet blasting uses abrasive media more efficiently compared to other methods. The water cushions the impact and creates the ability to control and filter to a very fine level, allowing the media to be reused for a longer duration before replacement, and adds consistency and repeatability to process. This results in cost savings over other methods, and a more accurate level of control over your process.

Enhanced Worker Safety: The reduction of dust and the generally lower abrasive impact contribute to a safer working environment for operators. Wet blasting helps mitigate health risks associated with exposure to airborne contaminants, improving overall workplace safety.

In summary, wet blasting provides a combination of precision, environmental responsibility, cost-effectiveness, and safety benefits, making it a superior method and attractive option for various industry applications

Process driven Solutions for Hob manufactures

Our aim is to work with you and supply you the process and solution(s) to meet your requirements.

Our equipment is designed to best utilise our process to meet your requirements. By utilising our years of experience and process knowledge, and combining it with our automated technology, we can provide a complete solution that delivers control and consistency to give you the perfect finish every time.

Contact us to discuss your requirements, and how we can work with you. Or have a look at our solution pages for more information.

We also design and manufacture washing equipment which in many cases complements our wet blasting solutions.

In many applications we have implemented solutions that incorporate both blasting and washing in a one step process which can remove handling steps and increase efficiency.