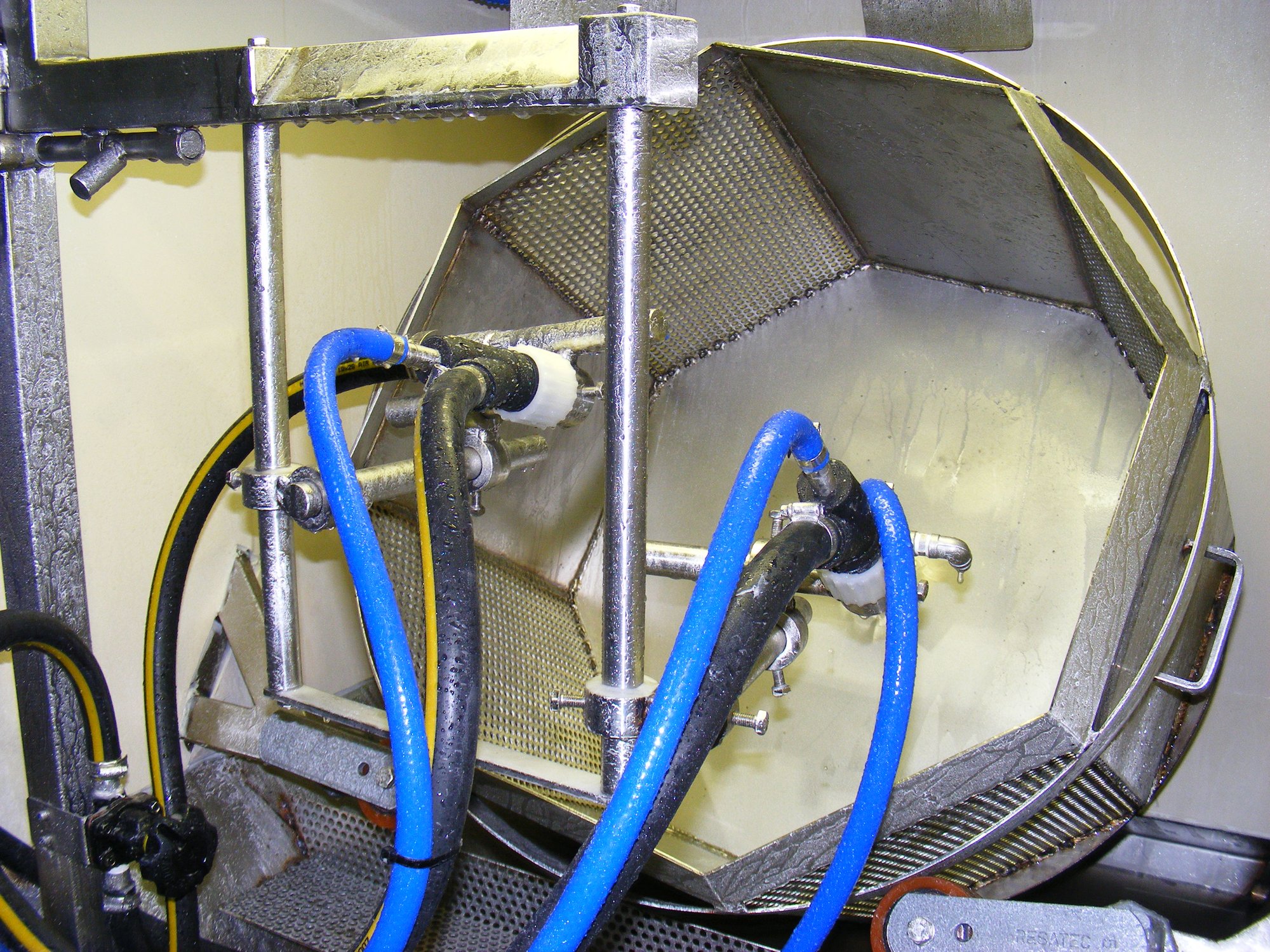

Aquablast® Tumbler

The Aquablast® front loading tumbler operates using a PLC controller. This controller is programmed with the various functions needed to produce a consistent finish on batches of components. Various drum designs and rinse options are available.

The Aquablast®/wet blast principle uses a mixture of abrasive and water that is propelled to the blast gun. This ‘slurry’ is then accelerated using compressed air. When the slurry impacts with components to be cleaned, it can lightly degrease (if an additive is used in the water) and also create a uniform finish on the blasted components.

Aquablast® Tumbler

Our Aquablast Tumbler solutions offer the ability to batch process small to medium size components in one step.

The Tumbler can be refined to process with the correct amount of intensity for your components be that tumbling intensity, action or direction or that of the blast guns and process parameters.

These parameters can be decided on as part of our sample processing and subsequent process development to ensure full process control, consistency and results.

Our tumbler solutions can be made bespoke to your requirement with barrel sizes to match component size and quantity along with number of nozzles. You can see out other tumbler solutions such as our small barrel and Tumbler line that will blast and wash components in a one step process.

Our Tumblers and Tumbler lines are being used in industries such as:

Additive manufacturing: To Tumble batch parts for post process power removal and surface smoothing.

Fasteners: For the cleaning and surface prep of fasters from composite to Titanium fasteners. removing scale and other contaminants as part of the manufacturing process

Process driven solutions

Our aim is to work with you and supply you the process and solution(s) to meet your requirements. This can be done with one of our manual or automatic solutions.

Many of our solutions, even the standard offering will be bespoke for your specific requirement. 99% of the time even the standard solutions have some bespoke nature to tailor them to each individual requirement. However, we also build a large amount of bespoke solutions for niche markets or industries. please contact us to discuss any requirements so that we can work together to offer the best solution for your requirements.

Our equipment is designed with our process and your requirements in mind whilst utilising our years of experience and process knowledge twined with our automation, we can provide a complete solution that delivers control and consistency to give you the perfect finish every time.

Go to our solution pages, or contact us below

We also design and manufacture washing equipment which in many cases complements our Wet blasting solutions.

In many applications we have implemented solutions that incorporate both blasting and washing in a one step process where needed which can remove handling steps and add increase efficiency.