Aquablast® Bespoke Solutions

All of Our Equipment Has a Bespoke Element

Every Aquablast machine and solution we offer includes a bespoke element. It's rare that we send out two machines exactly the same — even small variations such as optional features selected by individual customers make each unit unique.

If our standard range doesn’t include exactly what you need, we also offer fully custom-built solutions. We’ll work with you to design and build equipment tailored specifically to your process and requirements.

Aquablast® Bespoke Solutions

Our in-house bespoke design team works closely with each customer to fully understand their processes, goals, and challenges.

This collaborative approach enables us to tailor every solution to maximize operational efficiency and reduce the cost per component — ensuring optimal performance and long-term value from your investment.

If our standard range doesn’t quite meet your needs, we also offer fully custom-built systems. From initial concept through to final build, we design equipment specifically around your unique requirements.

A Tailored Process from Start to Finish

We support you at every stage to ensure your investment is the right fit — technically, practically, and commercially:

-

Free Sample Processing: We begin by testing your components at no cost to demonstrate the results you can expect from our process.

-

Process Approval: Once the process is validated and approved by you, we move forward with tailoring the solution to your needs.

-

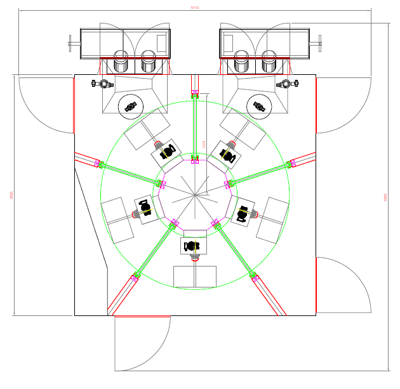

Automation Options: We explore manual, semi-automated, or fully automated solutions depending on your production goals and budget.

-

Integration with Existing Processes: We design systems that fit seamlessly into your current production line, taking into account:

-

Available floor space

-

Workflow orientation

-

Operator access and safety

-

-

Commercial Viability: Every solution is developed with ROI in mind, ensuring your investment makes sense from both a productivity and cost-saving perspective.

All of our solutions including wet blasting, ultrasonic solution, washing & degreasing, Drying, Chemical soak and agitation can be used in multiple process solutions to aid complete automation.

Contact us to discuss your requirements and ideas of how you would like a solution to work and we will use our expertise and experience to work with you to design, manufacture and deliver the perfect solution bespoke to you.

.png?width=450&height=395&name=robowash_0%20(1).png)

Process driven solutions

Our aim is to work with you and supply you the process and solution(s) to meet your requirements. This can be done with one of our manual or automatic solutions.

Many of our solutions, even the standard offering will be bespoke for your specific requirement. 99% of the time even the standard solutions have some bespoke nature to tailor them to each individual requirement. However, we also build a large amount of bespoke solutions for niche markets or industries. please contact us to discuss any requirements so that we can work together to offer the best solution for your requirements.

Our equipment is designed with our process and your requirements in mind whilst utilising our years of experience and process knowledge twined with our automation, we can provide a complete solution that delivers control and consistency to give you the perfect finish every time.

Go to our solution pages, or contact us below

We also design and manufacture washing equipment which in many cases complements our Wet blasting solutions.

In many applications we have implemented solutions that incorporate both blasting and washing in a one step process where needed which can remove handling steps and add increase efficiency.